Provide Professional Solutions

We have a variety of product solutions to meet the different needs of customers, our efficiency is high, service quality, customer praise.

Introduction to the Direct Torque Control Technology of Motor Control

The DTC technology originates from ABB and was patented in the mid-1980s. In 1995, ABB launched the first AC drive with direct torque control into the market, and at that time, DTC already held a leading position. Subsequently, with continuous improvements in aspects such as the computing power of processors, application programming, and communication interfaces, the performance of DTC has been continuously enhanced.

Control principle: DTC directly controls the magnetic flux and torque of the motor, unlike AC vector drives and DC drives which control the motor current indirectly. It regards the motor and the inverter as an integrated whole. By using the spatial voltage vector analysis method, it calculates the magnetic flux and torque in real time within the stator coordinate system. It directly controls the torque through a Pulse Width Modulation (PWM) inverter, avoiding thecomplex processes of stator current decoupling and vector transformation.

A.Celli Paper has a long experience in paper and tissue paper machinery and equipment market, offering advanced solutions for complete turnkey plants, tissue machines, winders and rewinders for tissue, paper and cardboard, roll handling and packaging. With the acquisition of PMT (formerly Beloit) in 2020, the company becomes the leading player in the sector with a 100% Italian ownership, extending its range of products and services to the specialty paper, graphic paper and packaging paper industries.

As the important role for paper automation ,Inomax VFD undertake important responsibility.

With high speed maxmium up to 55000 rpm.

high torque in low frequency,real 200% torque in 0hz.

100% energy feedback ,save electric power cost.

low harmonic with THDI

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the system, the flywheel's rotational speed is reduced as a consequence of the principle of conservation of energy; adding energy to the system correspondingly results in an increase in the speed of the flywheel.

Most FES systems use electricity to accelerate and decelerate the flywheel, but devices that directly use mechanical energy are being developed.

Advanced FES systems have rotors made of high strength carbon-fiber composites, suspended by magnetic bearings, and spinning at speeds from 20,000 to over 50,000 rpm in a vacuum enclosure.Such flywheels can come up to speed in a matter of minutes – reaching their energy capacity much more quickly than some other forms of storage.

Inomax four qudrant regenerative drive own the same technology than ABB and Siemens ,and with higher efficiency and user friendly as well as more competitive price.

For example ,our regenerative drive can control the wheels rotate at a high speed of 20,000-50,000 rpm.

Can make the THDI less than 3%, and 98% energy return back to on-grid power.

During the past 3 years, our regenerative drive are widely used in several flywheel energy storage manufacturers and got good reputation .

According to the UN, water scarcity is one of the major challenges facing the world today and tomorrow. The need to find sustainable solutions for new freshwater supplies is urgent; solutions that take the straight road from saline to fresh water at low cost and with minimum impact on climate and nature.

With electricity accounting for some 50 percent of the operational costs of

a desalination plant, energy efficiency and life cycle cost optimization are critical

challenges for utilities and developers. Inomax regenerative variable speed drives lie at the heart of maximizing plant efficiency and productivity levels.

Inomax four quadrant regenerative solutions that return energy savings of up to 65% compared to traditional centrifugal pump systems without energy recovery devices and drives.

To maximize production, your pulp and paper processes need to run reliably every single day.

Inomax variable frequency drives (VFD) are designed to provide reliable control over the speed and torque of motors so that they can run according to the precise demands of your process. From pulp processing to paper, board and tissue machines, using ABB medium and low voltage drives and motors means more efficient energy use, cutting your operating costs.

Inomax is professional manufacturer for VFDs,produce high performance ,direct torque control frequency drives,low harmonic drives ,AFE drives, multi-module drive ,liquid cooling drives, from 220V-10KVA,0.75KW-50000KW.with the same technology than ABB and siemens ,mainly focus on the area which have high request for VFDs and need cost effective solution than ABB ans siemens.

Inomax VFD are widely application for Metallurgy,Steels, Cement, Chemical, Oil & Gas, Power, Polymer & Rubber, Pulp & Paper, Sugar, shipbuilding,Mining,flywheel energy storage,thermal power,hydropower..

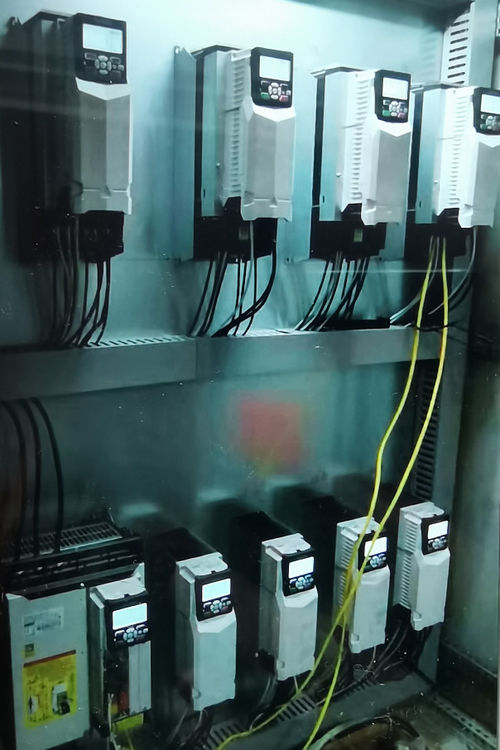

Inomax not only provide frequency drives ,but also provide complete solutions include the electric cabinet design,built and working together with other related devices.

Distributors ,project partners and system Integrator are welcome to talk more details for cooperation.

Mine hoist is a complex application in mining industries especially for big power and long distance.

The project we are going to share with you is the one for our Germany customer ,but end user is Russia customer.

The hoist motor is 560KW ,690V.

The key demand for technical request as below:

1. Low frequency operation time is long, such as 0.06hz-1.5hz operation for 1-2 hours every day, because this time is mine maintenance time-

2. The current output is very large when accelerating.

3. Energy feedback is required in 4 quadrants to save energy and reduce harmonics.

4. Some projects require synchronous excitation ,VFD should have synchronous excitation function.

According to their request, what we offer to them is our 690V 800KW regeverative drive ,but they finally choose 1000KW to ensure the VFD have enough overload ability.

because the running time is long during big load in low frequency.

What we offer to them not only the regenerative drive modules, but also the electirc cabinet.

Textile machinery demands robustness and reliability of its components. Harsh ambient conditions such as high air humidity, dust and fibres require application specific cooling concepts and solutions – Our products are designed to meet these specific demands.

INOMAX ACS580 drive with special software for textile machines,Start and stop without reversal, higher energy efficiency, short acceleration time can reduce yarn breakage

To produce 20% more, to start with inomax drives!

Whether your requirements are in municipal freshwater and wastewater treatment plants, desalination or irrigation plants, pumping stations or for water and wastewater networks, we have a full portfolio of variable frequency drives ,soft starters, motors for you to choose.

Your pumps and other motor driven applications all use energy. Optimizing those processes should be simple while making sure they function reliably. Our frequency drives with excellent application functionalities and features control water flow, pressure and level efficiently while reducing your energy bill.

Inomax’s medium voltage and low voltage AC drives have been widely used in municipal utilities, such as heat supply and HVAC applications, waterworks, and wastewater treatment plants. The company’s products and solutions offer high security and reliability, guaranteeing stable operation of municipal systems, and offering major energy savings.

Inomax is one of the world’s largest suppliers of AC drives for air compressors and has a leading position in many markets around the world.

Inomax products are used by a variety of world-leading air compressor brands. The company offers comprehensive solutions for air compressors, including advanced synchronous and high-pressure air compressor solutions, as well as a range of bespoke tailored integrated air compressor drives. Inomax’s air compressor solutions combine the control and drive systems to enable energy-efficient, stable air compressor operations.